Flip Flop Screen

Based on sorting solutions

MUNICIPAL SOLID WASTE SORTING EQUIPMENT

Bounce screen is also called specific gravity screen, Gravity Screen separate the material by different shapes and gravity. This is the ideal separating screen for domestic waste, kitchen waste, paper recycling, etc. Gravity Separating Screen drives shaft up and down the screen plate for moving forward and backward, shaking materials on sieves and disperse into heavy, rolling 3D materials (such as plastic bottles, wood, cans, etc.) and light, flat 2D materials (flm, paper, cardboard, sawdust, wood processing waste, clay stone, etc.) and the materials under the screen (sand, food residue), which is convenient for the next processing.

Under the action of the drive motor, the specific gravity shape sieve passes through the active and passive transmission mechanism and support of the active shaft, passive shaft and eccentric wheel. An equal four-bar machine formed by the connection between the support base and the sieve plate, the sieve plate produces a reciprocating circular motion similar to bouncing, and the material input from the feeding port is divided into two parts. There are three kinds of separation, large particle size, heavy and rolling 3D materials with good rebound effect, and sieve materials with small particle size and poor rebound effect, large particle size Flat, lightweight 2D materials with poor rebound effect are received by three discharge hoppers respectively.

According to the different climbing ability and bouncing performance of different materials, it will be affected by the inclination angle during the screening process.

The overall lifting system adjusts the angle between the body and the sieve plate to adjust the bouncing lifting angle of the sorting material.

Note: In order to avoid damage to the sieve plate, the size and weight of the feed should be controlled to avoid affecting the sorting effect.

The specific gravity shape screen cannot be used for the sorting of large pieces of masonry construction waste and large pieces of solid waste. Such materials need to be pre-picked out before sorting.

The specific gravity shape sieve cannot be used for the separation of strong acid and strong alkali materials.

в—ҸThe body is welded with profiles, lining plate is made of wear-resistant steel. The equipment is strong and suitable for continuous operation.

в—ҸThe inclination angle of sieve plate and main body adjusted 12-20 degrees by hydraulic system.

в—ҸModular eccentric design, good performance, low maintenance cost.

в—ҸGear box adopt frequency control, Sieve plate slope adjustable, suitable for various materials.

в—ҸSieves hole adopt round or square( based on materials)

в—ҸThe machine sieve is composed of several wear-resistant steel plates.

Based on sorting solutions

Based on sorting solutions

Based on MSWsorting sorting solutions

Waste leachate treatment for w...

Polluted air filtration treatm...

Adopt programmable control sys...

Belt Conveyor for light waste ...

Plate Conveyor for heavy waste...

manual sorting room for manual...

Rotary drum dryer for drying M...

Refuse Derived Fuel (RDF) Maki...

Waste Baler for packing recycl...

Waste Shredder, Pre Shredder

Eddy Current Separator for was...

Separating oversize waste and ...

air separator for waste recycl...

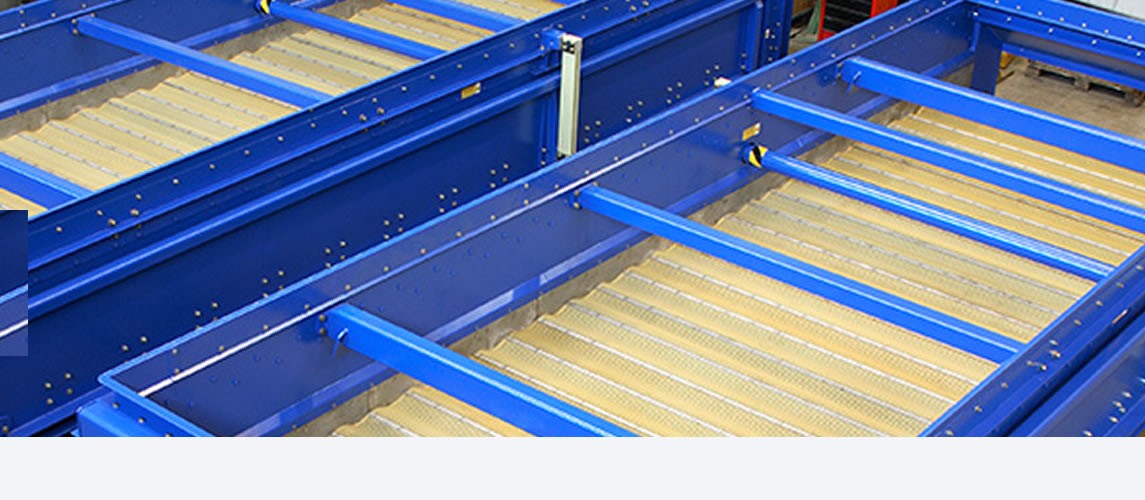

Ballistic Separator for 2D and...

Sorting and rycycling iron met...